-40%

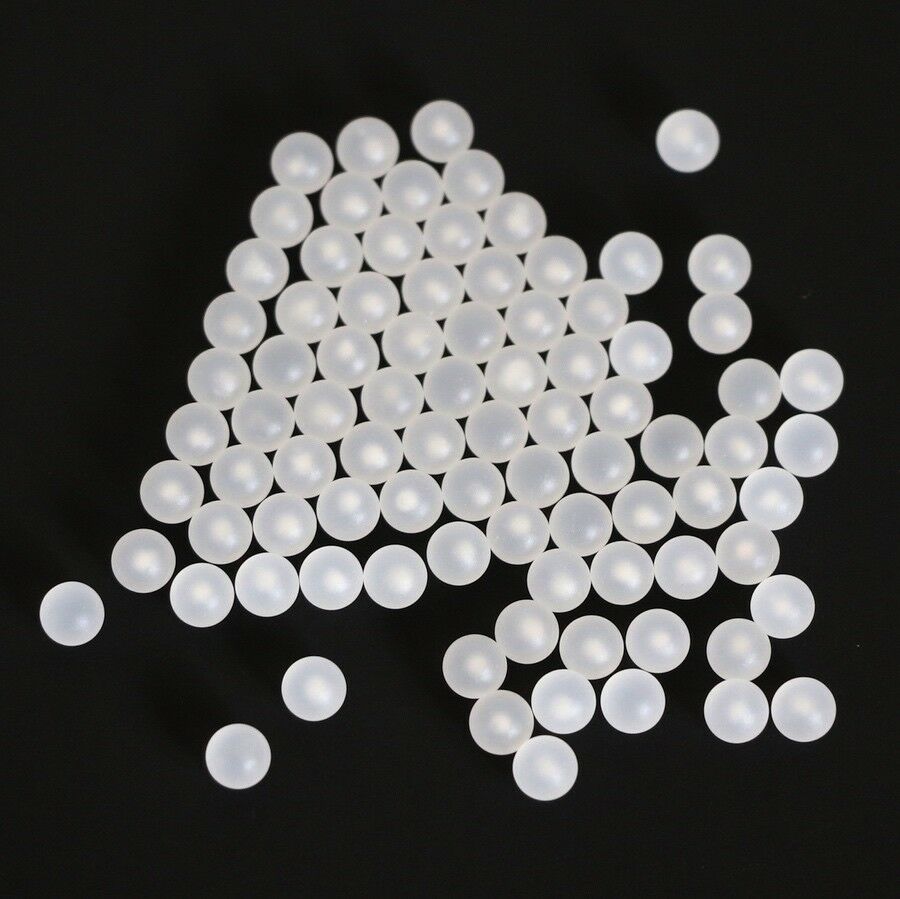

(Qty.10) S686ZZ (6x13x5 mm )Bearing 440C Stainless Steel Ball Bearings 686zz

$ 4.74

- Description

- Size Guide

Description

WHY 440C STAINLESS steel?Good corrosion resistance to water and many weak chemicals

Corrosion resistance can be improved by passivation

Good for temperatures up to 300°C

Slightly softer than chrome steel so lower load ratings

Will corrode in salt water or salt spray and poor resistance to acids/alkalis

More expensive than chrome steel

TECHNICAL SPECS

Item: S686ZZ

Structure: Deep Groove

Material: 440C Stainless Steel ( prefix "S" )

Bore Dia (d): 6 mm

Outer Dia (D): 13 mm

Width (B): 5 mm

Closures: Metal Shielded(ZZ)

Lubrication: Grease

Magnetic: little

Hardness: 58HRC

Corrosion Resistance: General

Clearance: C0

Grades: ABEC Grades 1

Dynamic Load Rating (Cr) (Newtons): 920

Static Load Rating (Cor) (Newtons): 354

Ball Qty: 8

Ball Dia (Dw): 2.000 mm

Weight: 2.68 g

Quantity: 1 Lot = 10 PCS

What is 440C?

A martensitic stainless steel. It's composed of these major alloy elements (I don't list the minor elements since they don't play a major role):

Carbon: 0.95-1.25% This increases hardenability and wear resistance, but decreases toughness in higher amounts.

Manganese: 45% This is added to reduce brittleness and improve forgeability, hardenability, and reducing deformation.

Silicon: 30% This is a deoxidizer and improves hot-forming properties.

Chromium: 17.00-18.00% Added only to high alloy tool steels, this improves hardenability, high wear resistance, toughness, and corrosion resistance.

Molybdenum: 50% Improves deep hardening and toughness.

These basic elements (along with iron) are a simple combination that works well together, and has for many decades.

This alloy is technically classified as UNS (Unified Numbering System) S44044. It's also classified as SAE (Society for Automotive Engineers) as 51440C.

The American Iron and Steel Institute classifies it as 440C martensitic standard stainless steel. Most modern knifemakers simply call it 440C.

DIMENSIONS